Friday, July 13, 2012

Jena Tec wins Nissan Automotive Retrofit Contract

Jena Tec’s automation division, Moss Group, received orders worth approximately £600,000 from the automotive sector. Notable amongst these is a £450,000 order from Nissan Manufacturing UK for the automotive transfer line upgrades for a new engine variant introduction - awarded by Nissan in May 2012 - and will comprise the supply and integration of conveyor systems, fixtures, transfer tables and ancillary systems. This will be integrated in Nissan’s Sunderland plant in December 2012, where Jena Tec will provide a complete turnkey retrofit, as Nissan UK expands its production capability for newer engine models.

The strategy for Jena Tec to provide precision OEM components, MRO repair services as well as full integration for complex machine tool retrofits and special automation projects. This is a demonstration of the company's growth to provide a vertically integrated service from design, engineering and implementation of automation solutions. For more information go to www.jena-tec.co.uk or visit www.mossgroupautomation.com

Jena Tec Ballscrew Investment Continues........

Jena Tec is pleased to announce the recent installation of its 3rd MBS (Miniature Ballscrew) Grinding machine in its German production facility in Jena. The NRK precision thread grinding machine will increase by over 50% Jena Tec's production capability in highly accurate ballscrews from 6mm to 12mm diameter used across a wide customer base for medical, optical and linear motion applications.

The universal CNC-thread grinding machine type NRK is designed for grinding of all kinds of external threads, e.g. worms, thread screws and thread gauges. Due to its rigid construction the machine makes possible a high productivity and precision. Using CNC-dressing technology the machine has a very high flexibility and can grind any

kind of thread profiles. The machine is equipped with the latest drive and

control technology (digital servo drives: Siemens, high precision scales and resolvers: Heidenhain).

The ongoing investment strategy of Jena Tec is to focus on niche areas of product development requiring demanding levels of accuracy and quality and further investment continues in the coming 12 months for additional CNC manufacturing technology related to ballscrew spindle and nut production as Jena Tec see growing demand for its high tech manufactured products. For more information please visit our website www.jena-tec.co.uk or www.jena-tec.com

Saturday, March 12, 2011

Jena Tec Wins EON Team National Safety Award

Avingtrans plc has announced that their operating company, Jena Tec has been recognised within the E.ON ‘SHE’ awards relating to safety, health and the environment for their work with the Connah’s Quay E.ON engineering team on a significant technical engineering development.

The SHE award Team Category was made to the E.ON Connah’s Quay team for their work with Jena Tec in developing an actuation system which offers greater safety in operation (than the traditional hydraulically operated actuators).

The Jena Tec team’s work involved development of an electro-mechanical solution to overcome the dangers of using hydraulics for operation of high force actuators (used to control turbine safety bypass valves for high pressure steam pipes).

Temperatures of 500°C are encountered and hydraulic fluid leakage was a known fire risk with the potential of causing major damage to the turbine installations.

Installation of nine replacement units took place at the E.ON Power Station in Connah’s Quay, United Kingdom following design and development by the Jena Tec team technicians over the previous three years. E.ON report increased levels of operational safety and decrease in maintenance costs relating to the actuation systems.

Paul Ward, Managing Director of Avingtrans Industrial Division maintains that the successful application of automation grade mechanical precision actuation to the arduous E.ON application is a great case study for a multi-disciplinary approach to engineering solutions. And this approach is enabling engineers to take advantage of modern control system technology to combat safety and environmental issues. He says that the Jena Tec’s investment in this sector of technology has great growth potential worldwide not only in hydraulic replacement but also pneumatic, fuel valve regulation, fire arrestment technology and many related fields.

For further information go to www.jena-tec.co.uk or www.valve-actuator.net

Thursday, February 10, 2011

€2.2 m contract win for Jena Tec Medical Components

Jena Tec, the designer, manufacturer and supplier of critical components and associated services to the energy, medical, industrial and global aerospace sectors, announces that it has signed a 3 year agreement with a leading European medical equipment manufacturer, where Jena Tec will supply high precision miniature ballscrews for use within a range of equipment by the customer.

The total contract value is approximately Euro 2.2m over three years and will commence in Q4 2011 before full production volumes are added in 2012.

The components within specialised medical equipment require suppliers of exceptional quality and delivery reliability and this agreement further bolsters Jena Tec’s planned growth in this high tech area. Jena Tec continues to invest in this growing area of medical instrumentation through increased testing and production facilities at its state of the art German facility.

Paul Ward, Managing Director of Jena Tec commented: “This is another example of Jena Tec’s transformation to a full service industrial partner to our major customers and it clearly demonstrates the long-term commitment to world-class quality and delivery”.

New Face Joins Jena Tec in Business Development

February sees a new member to the team in Dave Cloake appointed as Business Development Manager to Jena Tec UK focusing on the MRO sector (Maintenance Repair and Overhaul). Having worked in the Automotive industry both with Ford and Toyota, Dave moved into the service sector in the field of asset repair for critical machine tool electronic components and assemblies servicing the major automotive OEM's and 1st tier suppliers. Now with Jena Tec UK, Dave brings a wealth of experience to the company to expand our service capability and support for our growing customer base.

Friday, June 18, 2010

Dual Grinding Spindle Offers High Productivity and Small Footprint

The remit from the customer was simple, design and produce a grinding spindle that can do two jobs in one with 2 different grade fixed wheels. Sounds easy, but the solution to develop a grinding spindle able to grind with two different wheel grades without the use of an expensive tool changer mechanism demanded the combination of the experience of the customer (A leading player in the manufacture of grinding machines for the renewable energy sector) as well as the full linear and rotary motion background of Jena Tec working as a team to develop a highly customised spindle suitable for a demanding grinding operation.

Jena Tec's solution was to develop a motorised spindle capable of grinding speeds up to 6,000RPM with a special splined dual shaft arrangement utilising a highly effective seal and bearing arrangement which allows a static position rotating outer shaft to hold a large diameter grinding wheel while maintaining a smaller diameter inner grinding wheel maintained in a fixed rotational position from inner to outer wheel. Utilising Jena Tec's precision linear motion components, the system uses a servo drive and gearbox arrangement to extend the inner shaft and wheel very precisely when required while keeping very accurate run out and stability. Through spindle coolant was also required and achieved through the use of a specialist Deublin coupling. Another customer demand was to use spring water cooling which meant providing specific elements of the machine tool spindles in corrosion resistant materials.

The key benefit to the customer was that they can combine roughing and finishing operations with 2 different wheels on the same machine tool spindle thus saving the number of fixed position spindles needed within the machine layout, reducing handling time in between operations and also machine footprint. This contributes to the customer being able to offer a much more competitively priced machine tool system with higher productivity compared to their existing competition.

The Jena Tec dual spindle was designed and delivered in adherence to demanding customer build schedules and is another clear example of Jena Tec's specialist area of product development to support OEM machine tool makers product introduction and technology development.

For more information please go to www.jena-tec.com or email sales@jena-tec.com

Jena Tec Systematic Contract to Automotive Tier 1 Supplier

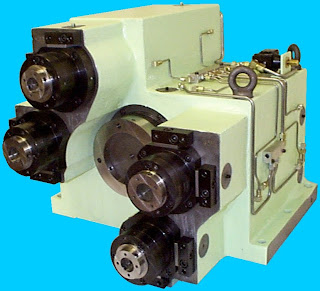

The Systematic Multi Head range now exclusively manufactured by Jena Tec provides a wide range of engineered solutions for High Productivity Machining. Our experienced engineers can design or retro-fit our multi head components into your machining centre to maximise the productivity demands of today's environment, offering you time and cost savings in the manufacturing process.

In June 2010 Jena Tec is pleased to announce a significant value contract win to a leading UK tier 1 supplier to an automotive OEM for diesel engine components. The Jena Tec remit was to re-design a range of multi head systems and replace an aging Marwin 3 machine transfer line of rotary transfer systems with new slideways and multi head drilling systems to enable a new diesel engine variant component to be produced using an existing line. As space was at a premium, investment in additional machine tools to satisfy production and also the high capital cost meant that Jena Tec's Systematic upgrade option was the preferred option in terms of timing, cost and floorspace to allow the customer to meet rising demand for production of new engine types.

The scope of supply includes the design, manufacture and retrofit of a complete series of CNC machine tool systems with more modern technology and machine tool components allowing faster productivity and throughput. The complete project will be designed, installed and commissioned by January 2011. Jena Tec's investment in the brand name of Systematic, a well known respected name in the automotive industry has secured their position in the niche engineering sector and takes advantage of a shrinking skill set for this type of work available in the UK. Export potential of this high precision sector of the machine tool industry is showing positive indications as Jena Tec capitalise on their global distribution network and group companies particularly in mainland Europe, USA and Asia.

For more information contact the Jena Tec team on +44 (0)1623 726010 or email at sales@jena-tec.com

Subscribe to:

Posts (Atom)